How To Calculate Upper And Lower Specification Limits In Excel

There is no lower specification limit LSL. In simple words it measures producers capability to produce a product within customers tolerance range.

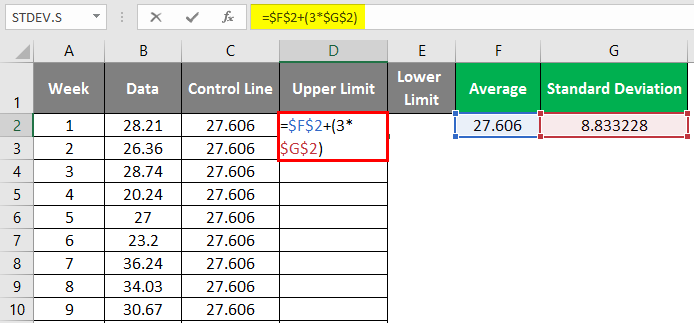

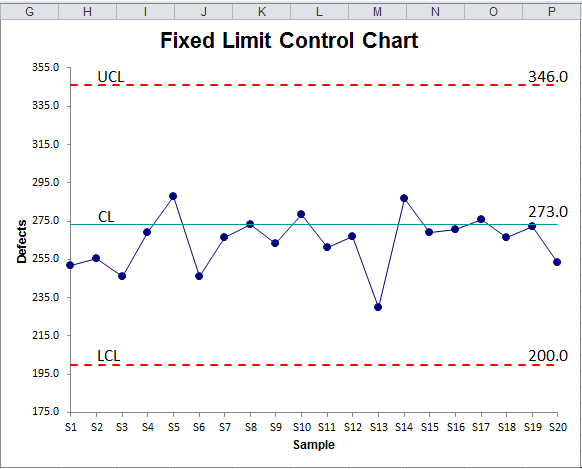

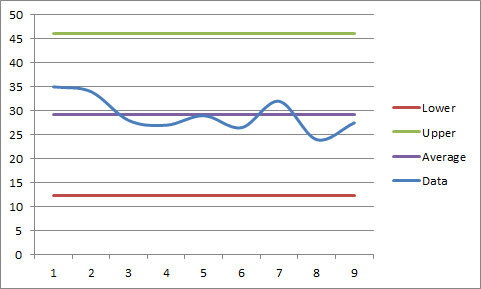

Best Excel Tutorial Chart With Upper And Lower Control Limits

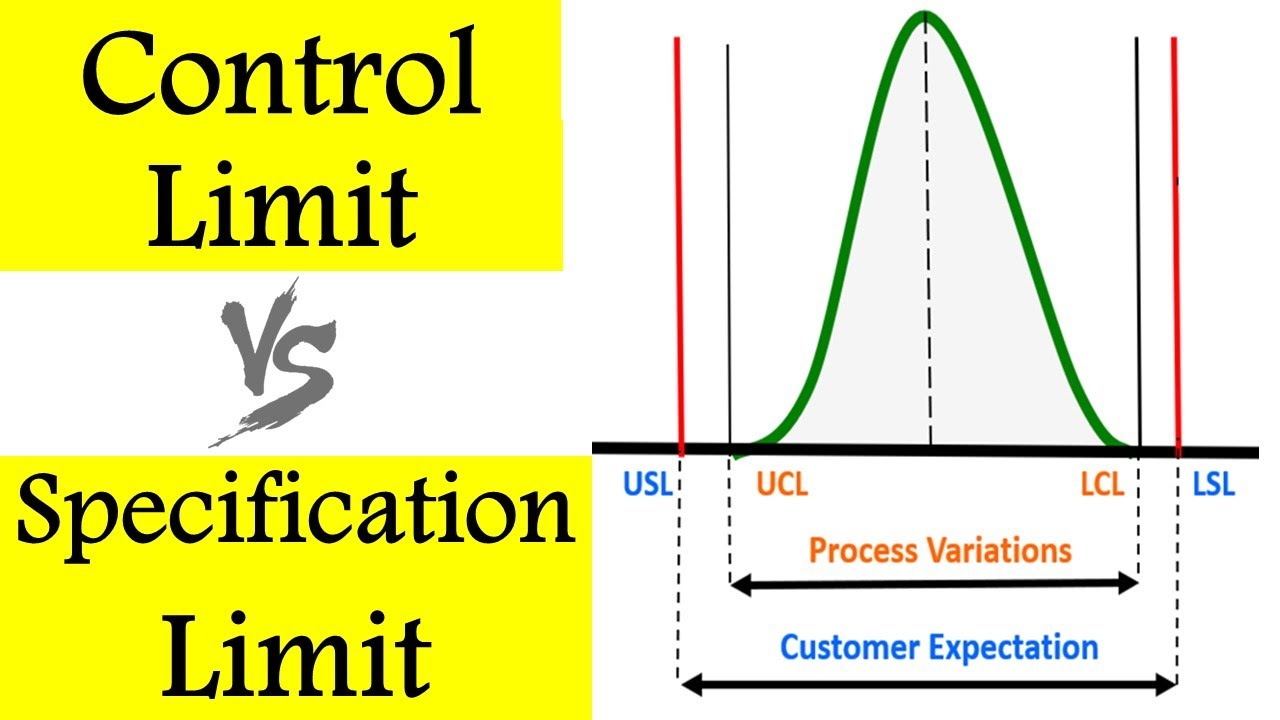

Figure 1 shows the general set up for determining a process capability index based on the upper specification limit USL with s being a measure of the process variation.

How to calculate upper and lower specification limits in excel. If you dont have spec limits use the maximum and minimum values. You can use it on the shop floor to monitor the Process variation. You can do this by setting upper andor lower specification limits for the continuous data set.

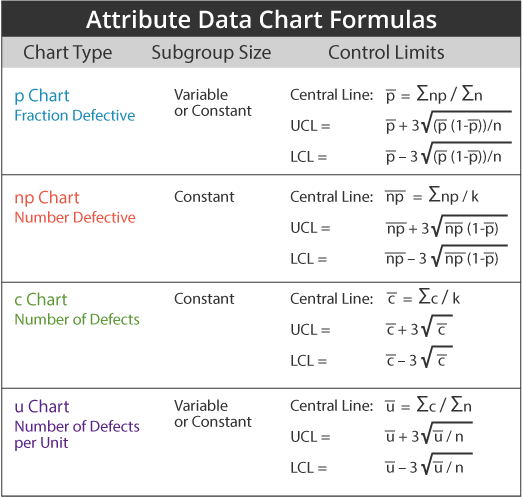

The limits are also referred to as tolerance limits and thus LTL and UTL. There are two calculations from the formula providing two values for Cpk. Collect the data and put into Excel template The Upper Control Limits UCL and Lower Control Limits LCL will be calculated.

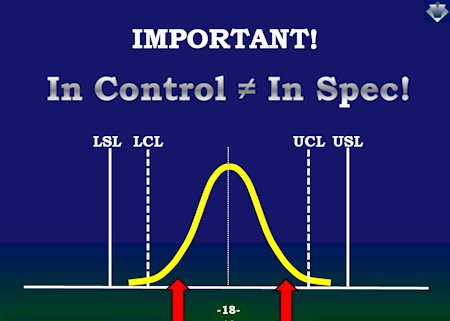

Therefore the upper control limit does the following three things. VOC is given by the customer whereas VOP is the processed voice it comes inherently from the data and creates the Upper Control Limit and Lower Control Limit. Upper Limit is the confidence interval of Cpk.

Process capability index Cpk is a statistical tool to measure the ability of a process to produce output within customers specification limits. Lower Limit and CI. Cpk is a measure to show how many standard deviations the specification limits are from the center of the process.

How to plot the Run Chart in Excel. Noise can be calculated in many ways and most of us are doomed to use what ever. Hubaux GVoss Decision and detection limits for linear calibration curves AnalChem.

Others require an equation. The customer defines the desired result by a value to be achieved and two specification limits. It addresses skills that may not be covered in most Excel for civil engineering texts such as step by step guides to create an application program and how to convert the.

The upper control limit is based on the process data itself. While VOC gives Upper Specification Limit and Lower Specification Limit it can only be. Edexcel GCSE Maths Specification All students are expected to know content in black r ed text r efers to higher tier only Specification below taken directly from edexcel website By Sophie Drew Number Structure and calculation N1 order positive and negative integers decimals and fractions.

Jurans Guidelines for Number of Bars. Press Control indicators button to maintain other important data like lower and upper limits ie. A run chart is also termed as Line Chart.

To find Cpk you need to calculate a Z score for the upper specification limit called Z USL and a Z score for the lower specification limit called Z LSL. Answer 1 of 9. Because the UCL is based on the process measure it gives you a.

Calculate the outlier cutoff cut_off iqr 15 lower upper q25 - cut_off q75 cut_off. Methods and Practices for Setting Speed Limits. X-bar and X-double bar the average of the averages which is represented on the X- bar chart by a solid centerline are also calculated.

The old CHIINV function up to Excel 2007 only returns the right-tailed probability. This is the upper specification limit USL for our process. When I used the formulas on this webpage in Excel 365 utilising the CHISQINV function I got unexpected results.

In the run chart you could able to set-up the mean value upper specification limit lower specification limit Median mode. Upper and lower specification limits are determined by the customer of the process. Step 3 Maintain the upper and lower limits In this step after pressing control indicator button the small screen will pop up where we will maintain the lower and upper limit data.

Customer requirements are defined using an upper specification limit USL and a lower specification limit LSL. Calculate bin intervals in Excel by taking the beginning value the bin width the bin width etc. Upper and lower limits calculator.

The tolerance also called tolerance width represents the distance between LSL and USL. Process Capability Analysis in Excel Calculate process capability metrics in seconds using QI Macros add-in. We can then calculate the cutoff for outliers as 15 times the IQR and subtract this cut-off from the 25th percentile and add it to the 75th percentile to give the actual limits on the data.

Cpk also requires input from the customer for the lower specification limit LSL and upper specification limit USL. Cpk is used to estimate how close you are to a given targe. -Calculate Cp V alue as well as Cpkl and Cpku - Minimum value from Cpkl and Cpku is the value of Cpk - By observing results of statistical analy sis one can be explain or determine future.

A Run chart will not able to give an idea about the control limits. Its a Excel basics book that every civil engineer should have read by now. Download Version PDF 727 MB Note.

Anything between the upper and lower specification limits can be called non-defective. Cpk is equal to minUSL -μ μ - LSL 3σ where USL and LSL are the upper and lower specification limits μ is the process mean and σ is the process standard deviation. Think of these specification limits as goal posts.

This document has been converted from the original publication to 508-compliant HTMLThe formatting has been adjusted for 508 compliance but all the original text content is included plus additional text descriptions for the images photos andor diagrams have been provided below. Process Sigma is also known as Six Sigma and both the terms are same. The natural variation in the process is taken as being 3 times the process standard deviation.

Any data point above the upper specification limit or below the lower specification limit can be called defective. Provides you a guide to what is really happening in your process The upper control limit is not a requirement like an upper specification limit is. Select the MINIMUM value as the Cpk and to serve as the baseline value.

Lets say you have 2 different inputs First for X and second for Y And you want to know the percent of each input to the total It will look like. 2 ways to calculate Six Sigma for Continuous and Discrete data Learn Process Sigma calculation in simple easy steps without the need of using any calculator you can use Excel to do all your calculations. You have collected the data in Table 1 and now want to determine if the process is capable of meeting the specification set by management.

A capable process meets customer requirements 100 of the time. Use the symbols. This minimum value must be equal to or greater than the minimum acceptability level.

Specification range in which material would be accepted. On some processes you can do this visually. Using this CHIINV function one must indeed use a2 for the lower and 1-a2 for the upper limit.

The limits are called LSL Lower Specification Limit and USL Upper Specification Limit. To perform a Cpk calculation two things need to be true.

Process Measurement Indices Spc Charts Online

Make Histograms In Excel Histogram Maker For Excel Excel Histogram

Control Charts In Excel How To Create Control Charts In Excel

Statistical Process Control Spc Tutorial

Calculate Capability Indices With Only One Specification

Process Capability Part 2 Bpi Consulting

Fixed Limit Control Charts Input Historical Control Limits

Process Capability Part 2 Bpi Consulting

Relationship Between Control Limit Specification Limit Advance Innovation Group Blog

Process Capability Part 3 Bpi Consulting

Upper And Lower Specification Limits In Normal Distribution Download Scientific Diagram

Upper And Lower Specification Limits In Normal Distribution Download Scientific Diagram

2 Ways To Calculate Six Sigma For Continuous And Discrete Data Sixsigmastats

Best Excel Tutorial Chart With Upper And Lower Control Limits

Best Excel Tutorial Chart With Upper And Lower Control Limits

Best Excel Tutorial Chart With Upper And Lower Control Limits

Control Limit Vs Specification Limit Difference Between Control Limits And Specification Limits Youtube

Create An Excel Control Chart To Analyze Data Pryor Learning Solutions

Spc Calculating Upper Lower Control Limits Youtube

Posting Komentar untuk "How To Calculate Upper And Lower Specification Limits In Excel"