How Many Types Of Cnc Programming Are There

Covering all options would fill volumes and isbeyond the scope of any one book or course. Types of CNC Programming Language.

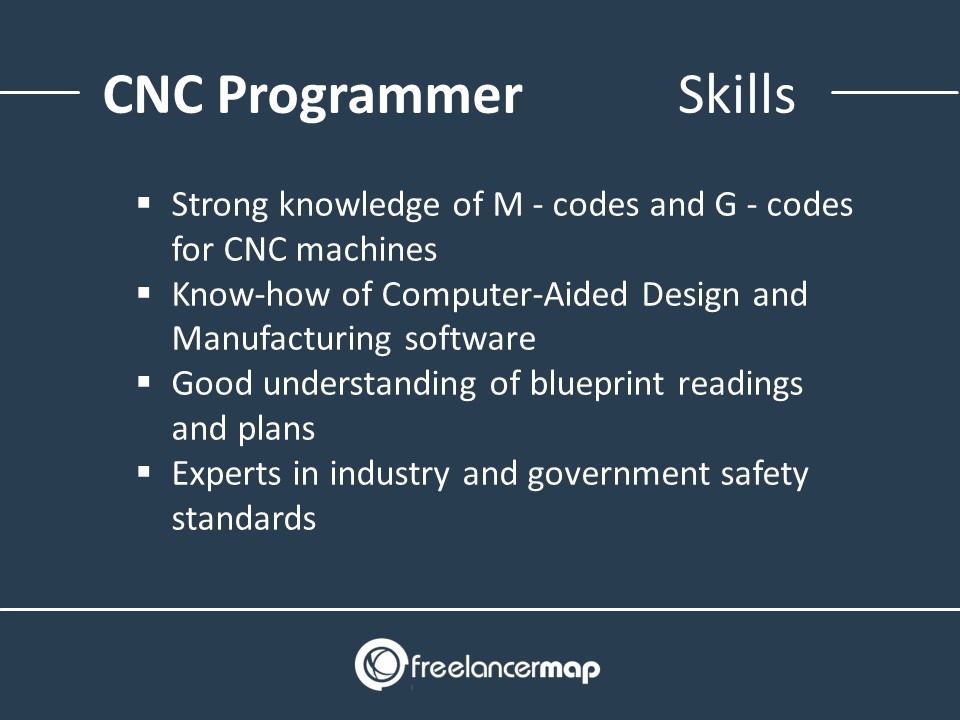

What Does A Cnc Programmer Do Career Insights And Job Profile

A typical CNC job will start by facing material to the highest flat surface of a part.

How many types of cnc programming are there. The two main types of PLC are fixed compact PLC and modular PLC. In manual lathing for example there must be a skilled technician for every machine while with CNC machining one skilled person can operate several machines. As the professional CNC machine manufacturer in China Blue Elephant CNC has provided customized CNC solutions for more than 8000 domestic and foreign users.

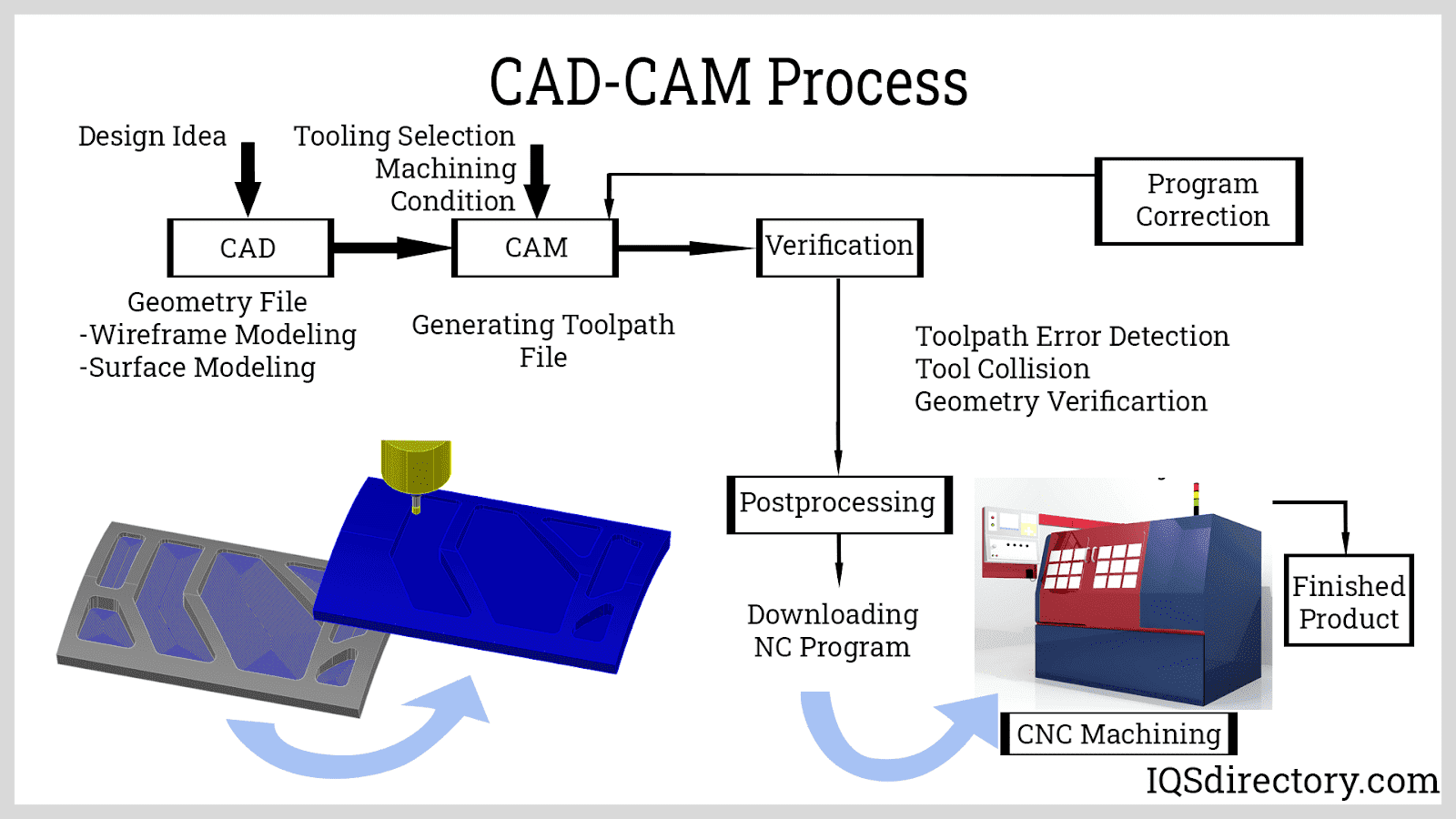

Knowing how to efficiently plan a 2D CNC machining project starts with understanding your toolpath types. 2 videostheory practice. There are two common types of power wood turning lathe machines.

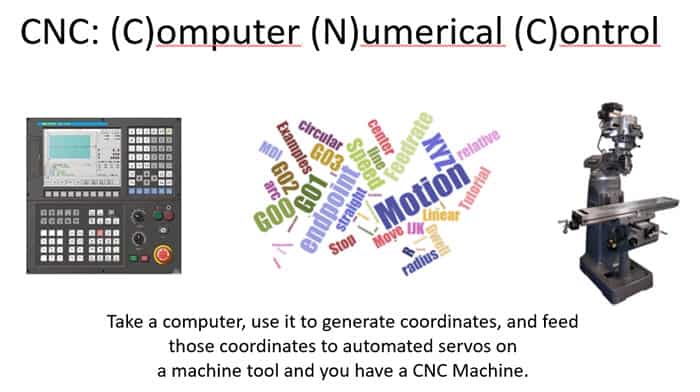

G-Code is known as one of the basic languages of CNC Programming and it is actually an ultimate guide to CNC G-Code Programming. Rather it is to show how to use CNC to make common types. There are 3 main configurations of these machines including 2D2 axis 3D3 axis and lastly tube and section CNC plasma cutters.

Within a single case there would be many modules. The goal of this course is not to turn and engineer into a journeyman machinist. The computer-numerical control offers a few types of financial and production advantages over the conventional method.

There are many types of G -Code files the most popular G-code file types are CNCNC andTAPFor simple requirements such as circles and lines you can easily create G-Code manually. The most common types of CNC plasma table kits include 4x4 plasma tables 4x8 plasma tables 5x10 plasma tables and 6x12 plasma tables in feet some user may call the CNC plasma cutting table kits as 48 x 48 types 48 x 96 types 60 x 120 types in inches some user may call the table kits as 1212 types. There are many different types of thread taps and knowing exactly when to use each will make your tapping faster and easier.

For 5-sided machining there are controls that allow machinists to program a 5-sided part without the need to buy a CAM system. CNC Training so you can get the best Material Removal Rates Tool Life and Surface Finish. Automatic wood lathe is refer to a type of power woodworking tool with computer numerical controlled all the work is automatic from the beginning to the end.

The first in this list is the most common which produces flat profiles and cut edges are at 90-degrees to the materials surface. But it is even easier to produce the same with the help of CAM software. CNC Feeds and Speeds Cookbook.

CNC Machining is a very broad subject and there are many ways to do most things. It helps in sharpening your skills so that you get to know about more CNC G-Code programming by covering a few topics from the basic CNC Programming all the way through to advanced topics like Macro B programming. Fully automatic CNC wood lathe and semi-automatic wood lathe.

There programmers also look out for alternations when the machine is all set for the process of manufacturing. It directs the machine on the speed and depth of the movement. So it does not have the capability to expand the modules.

Older CNC machines might also need a larger feed height so the spindle can reach full speed before plunging into the material. Free Feeds and Speeds Master Class. Wood lathe is a type of popular woodworking tool.

Weekly email CNC course will take you from Beginner to Expert. This is an important consideration when a shop is considers purchasing a 5-axis machining center to do 5-sided machining. Do you need a CAM system.

Every input and output would be decided by the manufacturer. More Feeds and Speeds. It has a fixed number of IO modules and external IO cards.

How Many Types of CNC Plasma Tables. Plus specific guides for cutters and material types. If youre familiar with tap types but need to learn best practices in their use to avoid breaking taps try our article and video 7 Ways to Avoid Breaking Taps.

Not all CNC plasma cutters are the same however. Quick Video Course in Feeds and Speeds. There are 5 different types of CNC Machines and not all of them can be run through a single set of programming.

Our main CNC machines include CNC routers laser machines a series of furniture production line equipment and so on.

5 Axis Machining Is It All It S Cracked Up To Be Cnc Training Centre

How Do I Become A Cnc Machinist Or Programmer Make It From Metal

Classification Of Cnc Machine System What Are The Types Of Cnc Machines Cnclathing

Cnc Milling What Is It How It Works Operations Overview

G And M Codes Understanding The Cnc Programming Languages

Cnc Machine Programming Operating Videos App Apps On Google Play

5 Common Cnc Machining Problems Errors And Solutions Cnclathing

Cnc Macro Programming Cnc Training Centre

Complete Guide To Cnc Software 21 Types Of Digital Tooling

What Are The Main Differences Between G Code And M Code While Operating Cnc Machine Quora

Cnc Programming With G Code Definitive Free Tutorial 2019

G And M Codes Understanding The Cnc Programming Languages

1 Introduction To Cnc Machines Co Develop Part

Complete Guide To Cnc Software 21 Types Of Digital Tooling

What Cnc Programming Style Best Suits Your Operations

Cnc Machine Types Parts Advantages Disadvantages Applications Specification With Pdf

Cnc Programming What Is Cnc Programming Autodesk

Cnc Programming What Is Cnc Programming Autodesk

Posting Komentar untuk "How Many Types Of Cnc Programming Are There"