Specification Process Limit

A process where the majority of all measurements reside within the allowable specification range is a. The following formula is used to calculate the CPK or process capability index of a given set of data.

What Is Six Sigma Concepts Principles Examples Sigma Process Improvement Dow Chemical

Specification Limits which shall be referred to in the following as the Watershed Tolerance.

Specification process limit. The value of Cpk is the minimum of two process capability indices. For a one-sided specification the goal is to maximize or minimize performance ie. LSL Lower Specification Limit and USL Upper Specification Limit These limits quantify the requirement of customer CTQIf our product falls in the range of USLLSL the product is said to be meeting our customers expectation.

There are 2 Control Limits. From the upper specification limit to the lower specification limit. Specification limits and control limits are used for different purposes.

A minimum of 3 defects will be made and more if the process is not centered. JOS Specifications are set to control and confirm the quality of the product for a specific qualifiedvalidated process. It is not likely your customer would be happy if you went with option A and decided not to calculate a Cpk.

One process capability is Cpu which is the process capability based on the upper specification limit. USL is the upper limit. Algebraically Cpk is defined as shown in the figure.

Purity or impurity there is no clear target and therefore margin is measured rather than tolerance. 96 Manufacturing Specifications If you want to have at least a 96 percent chance that the measured item is in spec when the measure-. A specification is defined as a list of tests references to analytical procedures and appropriate acceptance criteria which are numerical limits ranges or other criteria for the tests described.

Control limits are calculated from process data. Others require an equation. Specification limits then the difference between the Upper specification U and then mean or the difference between the Lower specification L and the mean should be larger than 3σ.

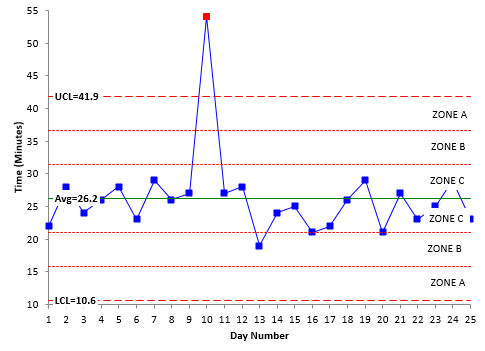

First off what are the specifications. Control limits let you assess whether your process is stable. Upper Control Limit ucl and Lower Control Limit lcl indicating the maximum and mininium allowable values respectively.

GHTF Guidance Annex A Statistical Methods and tools for process validation. One-sided specification limits consist of a single upper or lower limit restricting the characteristic. Specification limits are different from control limits as they are not calculated using means and standard deviations but are instead values determined by the designers via the customer to be within acceptable quality boundaries.

Going with option B you might argue that the lower specification limit LSL is 0 since it is impossible to have a moisture level below 0. Specification limit is the limit set by customer. The characteristic may exceed the limit in case of an upper limit or fall below the limit in case of a lower limit which proves nonconformity with specifications and thus leads to a product that is not okay.

As the process capability improves the variability decreases and it becomes more closely centred between the specification limits. Appropriate limit range or distribution to ensure the desired product quality. Using a traditional approach material specifications and process parameter ranges can be based.

The process is in statistical control. Cpk is a measure to show how many standard deviations the specification limits are from the center of the process. On some processes you can do this visually.

If P pk is greater than 1 then the process mean is sufficiently far from the specification limit. To find Cpk you need to calculate a Z score for the upper specification limit called Z USL and a Z score for the lower specification limit called Z LSL. So with USL at 5 and LSL at 0 Cpk is calculated as follows.

CPK Min USL mean3 std mean-LSL3std Where CPK is the process capability index. Specifications are set based on manufacturing experience and all other relevant information. To fit within the upper and lower specification limits.

Cp1 means that the process is just meeting specifications. Cp. Specifications are linked to preclinical and clinical studies.

The other is Cpl which is the process capability based on the lower specification limit. Cp USL LSL 6 sigma. To a specification method process or procedure.

When a tolerance is defined there is a clear target. They represent how your process actually performs. Potential drug substance CQAs are used to guide process.

Specification limits are defined by your customer and represent the desired performance of your process. By convention the Control Limits would usually be2 or 3 standard deviations σ from the target value though this will vary from process to process. Its natural for a manufacturing group to be concerned with a products specification limits the upper and lower limits imposed on the process.

This is a crucial distinction that is frequently confused. They are what is acceptable to the customer. Basically specification limits have to do with the voice of the customer while control limits have to do with the voice of the process.

Specifications are linked to analytical procedures. ICH Definitions - Specification zQ6A. Generally there are two types of specification limit ie.

Specification limits are sometimes designated by the producer definitions of quality or most frequently a customer in an attempt to narrow the distribution of a products properties.

Spot Colour Idea Really Wanted To Limit To 2 Colours Red Pantone 180c I Found Really Warming And Relatable To Red Win Spot Color Printing Spot Colour Colours

Use The Value Index To Prioritize Project Efforts Standard Deviation Prioritize Process Capability

Statistical Process Control Product Process Improvement Presentationeze Statistical Process Control Process Control Process Capability

Using Control Charts Or Pre Control Charts Pre Control Chart

Read More On Tipsographic Com Free Kanban Board Templates For Excel Google Sheets Functional Testing Software Testing Agile Software Development

Highlevel Summary Of Ideas On The Net Around Contracting Agile Business Management Leadership Management Agile Software Development

Fundamentals Of Advanced Process Control Process Control Fundamental Standard Deviation

Lean Six Sigma 101 Lean Six Sigma Lean Sigma Change Management

Specification Limits Proceed With Caution Statistical Process Control Process Control Limits

Cyberounds Cme Standard Deviation Health Professionals

Bubbaldrin Astronaut Art Drawings Space Art

093123 Figure3 Gif 358 339 Lean Six Sigma Statistical Process Control Leadership Training

Specification Limits Proceed With Caution Statistical Process Control Process Control Business Communication

What Are Natural Tolerance Limits Tolerance Statistics Help Game Programmer

Posting Komentar untuk "Specification Process Limit"