Specifications And Requirements For In-line Inspection Of Pipelines

To support any activity from a technical perspective regarding research development set-up of specifications set-up of good applications and information relevant for pipeline inspection and integrity at all levels such as but not limited to inspection integrity cleaning repair localization with a focus on In-Line-Inspection and continuous pipeline operation. O r g - 6 - Crack-like An anomaly feature similar to a crack with some volume and a displacement surface opening between 01 and 10 mm of.

Api Standards For Drill Pipe Inspections Turnco

B Wall thickness of the line pipe material c Type and Grade of line pipe.

Specifications and requirements for in-line inspection of pipelines. 49 CFR Part 192 establishes requirements for gas pipelines and 49 CFR Part 195 does so for hazardous liquid pipelines. Special marking WR for weld repair or NH for the non-hydro tested pipe. It is intended as an addition to the POF document Specifications and requirements for in-line inspection of pipelines in its latest revision referred to as PO Spec further in the present document.

In-line inspection contractor compliance check_Tables 2020-Pdocx In-line inspection contractor compliance check_Extra table 2020-Pdocx Specifications and requirements for in-line inspection of pipelines. Promote pipeline integrity management globally - global network to champion Work with industry to improve quality of pipeline integrity management and the services provided Upgrade and develop ILI In-Line-Inspection specifications best practices and other relevant documentation. Requirement is that in-line inspection tools should be designed intrinsically safe in order to avoid any safety issues during launching and receiving.

After launching the tools can not be accessed and therefore the inspection process has to be fully automatic and cannot be supervised. Specifications and requirements for in-line inspection of pipelines - Version 2016 P i p e l i n e O p e r a t o r s F o r u m w w w. Requirements for Oil and Gas Pipelines DISCUSSION DRAFT Page 4 of 8 1 An area containing a building intended for human occupancy such as a residence school hospital or business that is located within 300 feet of an active gas pipeline and that is not necessary to the operation of the pipeline.

Conquer First-Time Buyer Fears With Our Ebook. Ad Help Your Business Achieve EHS Compliance. The line and grade of the trench according to the cut sheet.

V The locations of the points at which other pipelines would be crossed by the new pipeline. Check each pipe length for cracks or imperfections. Tool specifications Tool specification shall include.

Iii Direction of fluid flow along the pipeline iv The locations indicated by symbols of any installations along the pipeline. Report processed data from an in-line inspection run. D Designed maximum operating pressure.

Once the pipe is cleared all test and inspection it is marked as per the standard requirements. PHMSA has established regulations governing aspects of pipeline design and construction and conducts inspections of pipelines under construction in order to fulfill this responsibility. P i p e l i n e o p e r a t o r s.

Specifications and requirements for in-line inspection of pipelines - Version 2016 P i p e l i n e O p e r a t o r s F o r u m w w w. P i p e l i n e o p e r a t o r s. Diametergeometry measurements Curvature monitoring.

Although the most common tasks required to pipeline inspection gauges PIGs are geometrydiameter measurement and metal losscorrosion detection the information that can be provided by these devices covers a much wider range of inspection and troubleshooting needs which include. Requirements related to pipeline design and construction are in Chapter 49 of the Code of Federal Regulations CFR. The Inspector must check the following while pipe is being laid.

Ad Create PACP certified surveys and reports with PipeLogixs easy to use software. Articulating and advocating the interests of the in-line pipeline inspection industry before legislative administrative. Make Compliance Easy Standardize Processes Make Impactful Safety Management Decisions.

The following shall be marked on the pipe. Ad Search and Buy API Petroleum Standards. Shall be compiled with companys specification.

Pipeline Inspections October 2020 In accordance with section 9 of the Pipeline Rules the requirements for the design construction testing operation maintenance repair and leak detection of pipelines are provided in CSA Z662 Z24511 Z24512 and Z24515 unless otherwise modified altered changed or replaced by the. Observe the pipe while being laid to be sure the pipe has full bearing and is fully into the pipe bedding and is centered in the trench. Wall thickness range The magnetic field strength H in Am-1 as function of wall thickness only for MFL pigs Speed range Temperature range Maximum pressure.

O r g - 2 8 - 7 Reporting Reporting is an essential part of the inspection process and depending on the time and information required by the Client various types of reports can be issued see below. Specifications requirements for an in-line inspection Technical requirements are covered by POF spec. Standardisation introduced by this document helps to compare different bids.

Promoting accreditation of the recommended practices under US and international standards. Specifications and requirements for intelligent pig inspection of pipelines Version 21 6 November 98 6 3. HSE aspects except ATEX liabilities paiements conditions.

Developing and proposing recommended practices and policies for in-line pipeline inspection that ensure high quality services for the safety of the general public and the pipeline industry. In-Line Inspection of Pipelines how to do it API 1163 In-line Inspections Systems Qualification Standard qualifies the tool ANSIASNT ILI-PQ-2005 In-line Inspection Personnel Qualification and Certification qualifies vendor personnel including analyst. This document has been reviewed and approved by the Pipeline Operator Forum POF.

Mfl Pigging Dacon Inspection Technologies

Predicting The Future Of Ili Tools

Mfl Pigging Dacon Inspection Technologies

In Line Inspection Dacon Inspection Technologies

Enduro Pipeline Services Digitel Flux Logger Data Storage Flux Logger

Regular Inspection And Technical Maintenance Of Natural Gas Engines Natural Gas Generator Maintenance Gas Supply

Levels Of Certification In Ndt Training Programs Training Programs Business Management Company

Concrete Slope Protection Standard Requirements Specifications Safe Work Method Of Statement Concrete Concrete Mix Design Protection

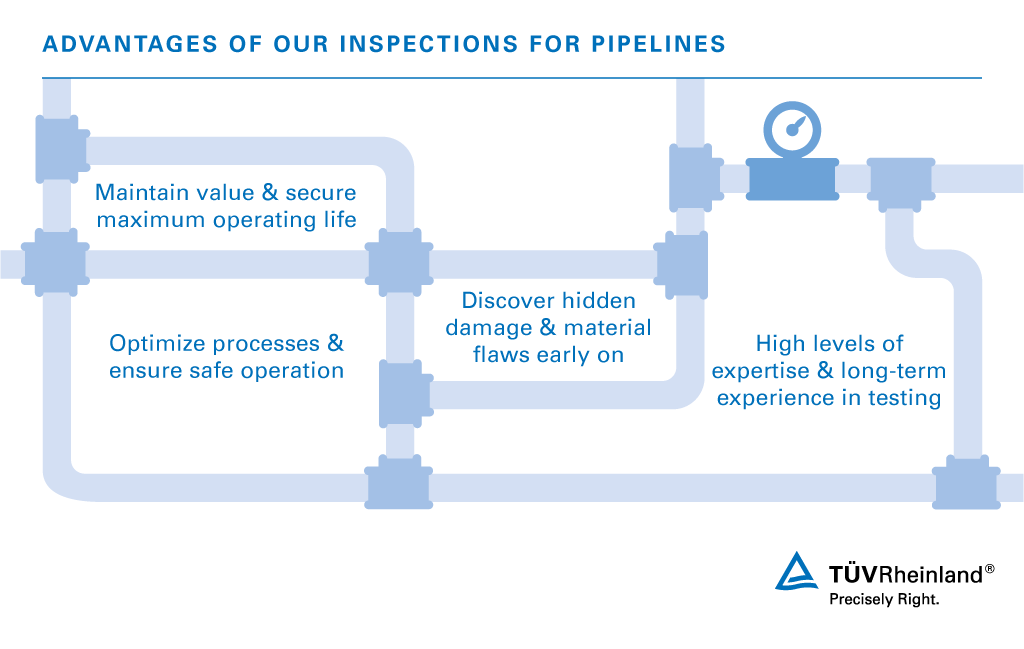

Pipeline Inspections Us Tuv Rheinland

Guided Wave Ultrasonic Testing Ultrasonic Testing Gas Industry Ultrasonic

T D Williamson Inline Inspection Ili

Guide To Pipe Measurement And Inspection Oms Optical Metrology Services Ltd

1 4 Aluminum Alloy Air Pressure Regulator And In Line Water Trap Filter In 2021 Water Traps Aluminium Alloy Air Pressure

What Is Welding Procedure Specification Wps Engineering In 2021 What Is Welding Welding Smaw Welding

Ndt Ili Services Pipeline Inspection Mistras Group

Pipeline Inspection An Overview Sciencedirect Topics

Guided Wave Ultrasonic Testing For Pipeline Inspection In Oil And Gas Industry Engineering Blog Ultrasonic Testing Gas Industry Oil And Gas

Posting Komentar untuk "Specifications And Requirements For In-line Inspection Of Pipelines"